TECHNOLOGY & SOLUTION

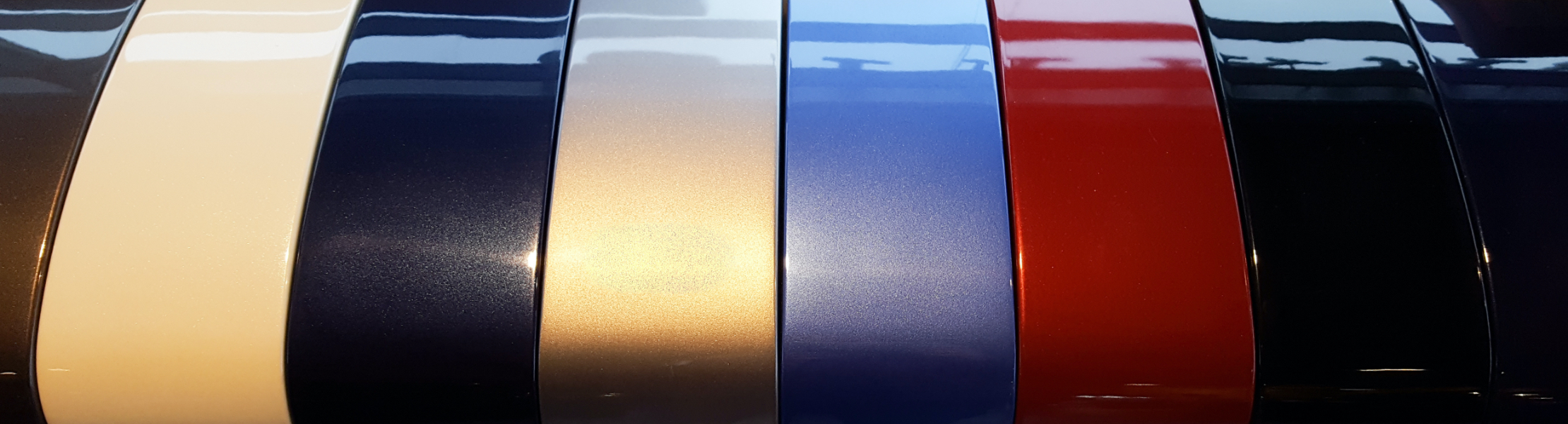

What's Coating?

In addition to anti-corrosion and protective function,

coating has been widely used for colorful cosmetic coating of things or tools in our everyday lives.

Coating is the formation of coating film on the surface by applying or spraying paint. It has been widely used for rustproof and protection as well as for decorating the living space and tools surrounding us beautifully and colorfully.

Also in recent years, in addition to function such as resistant to chemical, bacteria, water, fire and abrasion, consideration for the environment is also demanded.

High coating quality

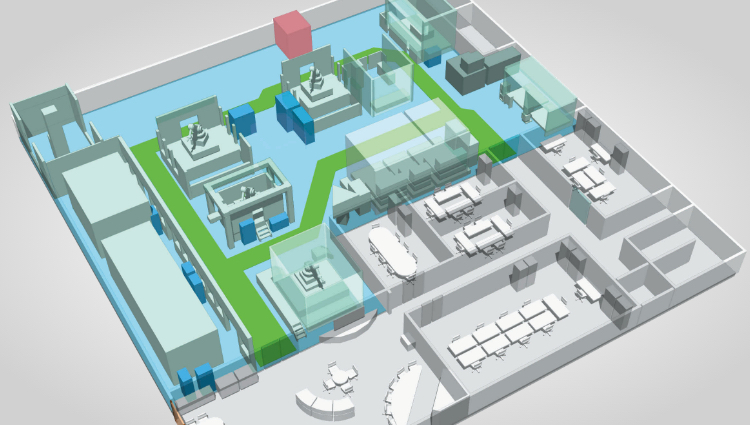

Coating technology that achieves high transfer efficiency and quality

Aim for transfer efficiency 100%

We believe that it is the mission of coating equipment manufacturers to develop technologies based on the keywords "Atomization,""Constant feeding," and "Correspondence to environmental paints," which are foundation of TE100, and we continueing to take on challenges every day.

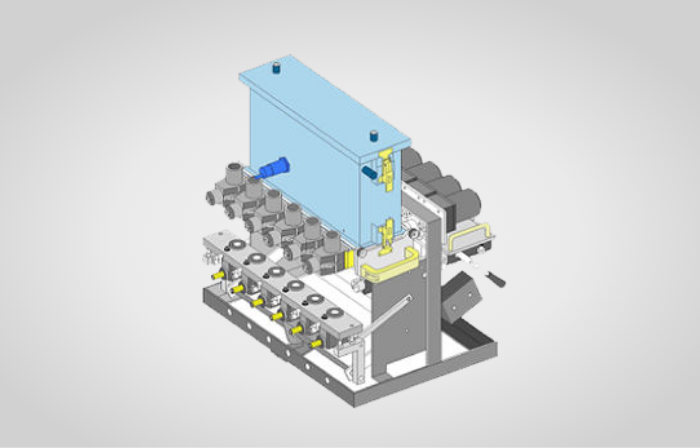

Air electrostatic spray gun

Air wrap spray gun

Rotary atomizing electrostatic coater

The constant feeding technology of ASAHI SUNAC is

a fusion of software development technology and high precision processing technology.

Constant feeding technology" for stable supply of paint is necessary for achieving high transfer efficiency and quality.

At Asahi Sunac, by combining the accumulated software development technology with the excellent high-precision processing technology of our own factory, we can propose not only general pump but also the most suitable specification for each customer's application such as "for viscosity paint","for large flow rate" and "high precision correspondence".

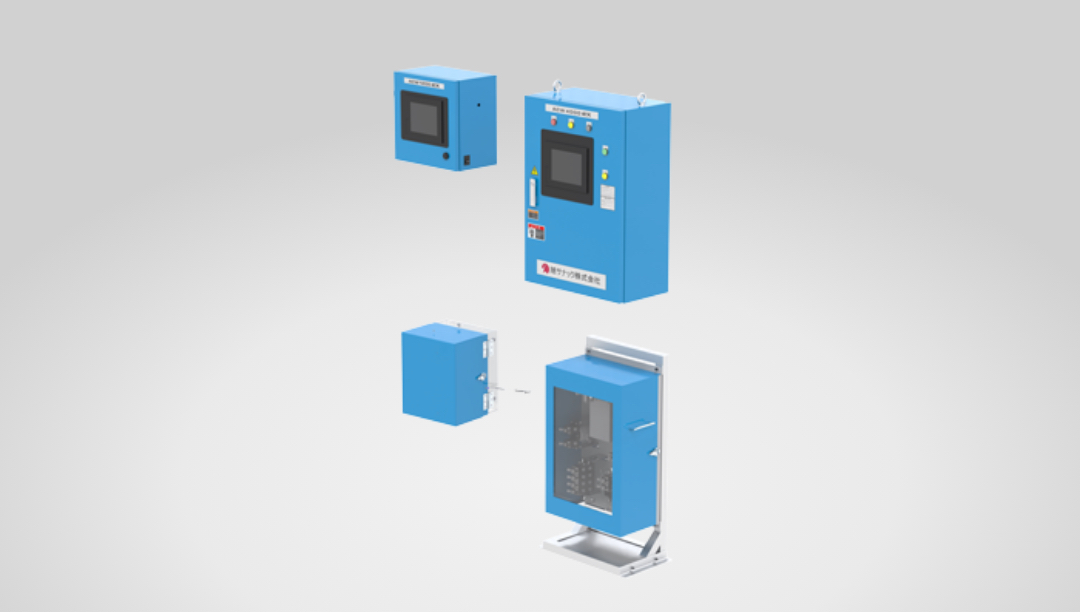

Volumetric feeder for liquid paint

Constant feeder for powder coating

Consideration to environment

Aim for environmentally frendly coating

Environmental paint

The solutions for reduce VOC (Volatile Organic Compounds) and CO2 emissions

In the past, paints containing organic solvents were widely used, but recently, coating technology that contribute to the reduction of VOC (Volatile Organic Compounds) and CO2 emissions are attracted attension from viewpoint of environmental protection. Asahi Sunac is working toward "Ec'Coater" so that we can achieve that at a higher level.

Our efforts

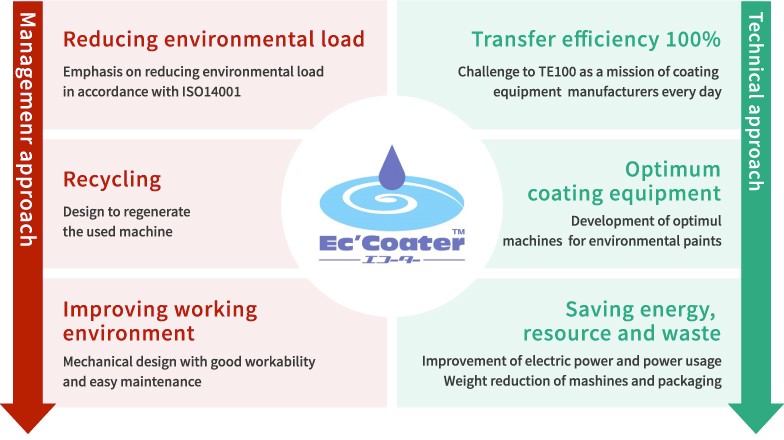

Innovation with the original concept "Ec'Coater"

for environmental protection and saving resource and energy.

The word "Ec'Coater comes from our attitude that basing the environment first in our business.

Based on the idea "Ec'Coater", Asahi Sunac continues to develop high-value-added coating machines and systems that can contribute to customers' business, both in terms of management and technology.

We will continue to challenge solutions by constantly incorporating the most advanced technologies such as IoT and deepening "connection", "communication" and "cooperation" with customers.

Please feel free to contact us for any inquiries or questions regarding the coating equipment and engineering.

Please feel free to contact us for any consultations or questions related to the services of Coating Equipment Division.