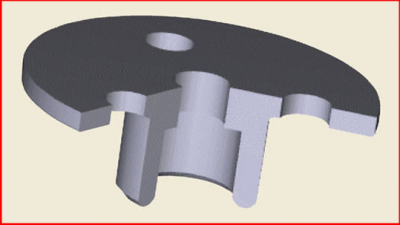

Phillips Flange Shaft

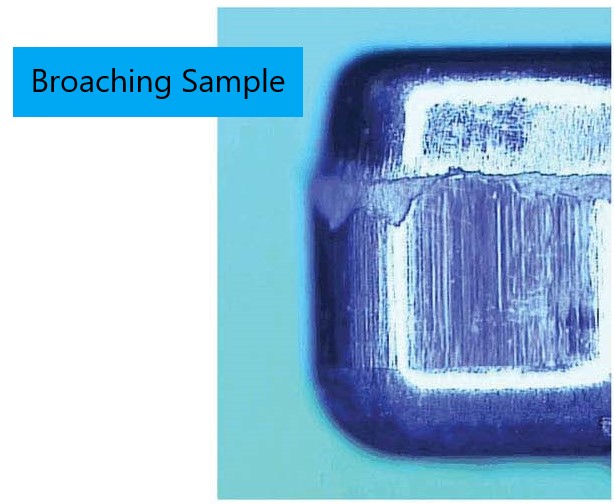

Case study of burr free broaching

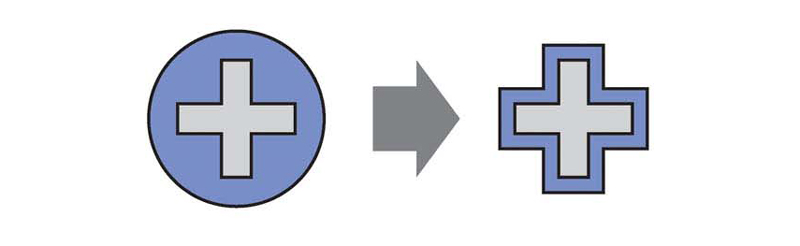

Conventional

Broaching in forging causes punching burrs.

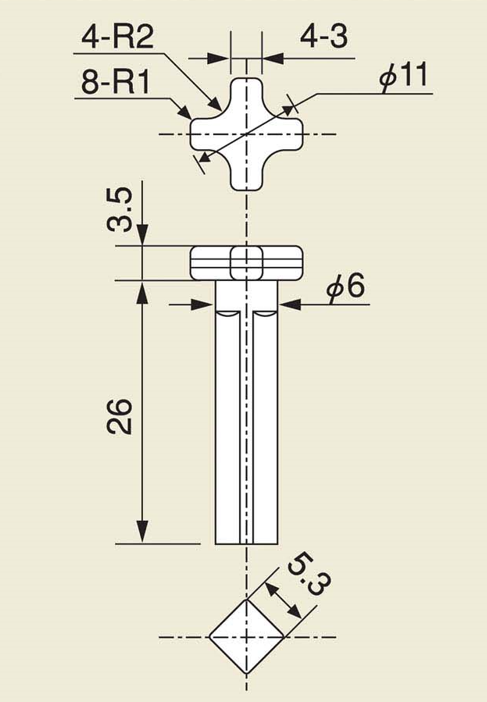

Condition

| Machine Model | AQ675-3 |

| Production Speed | 165 rpm |

| Material | S10C |

Point

①Broaching is stable by making allowance even and thin.

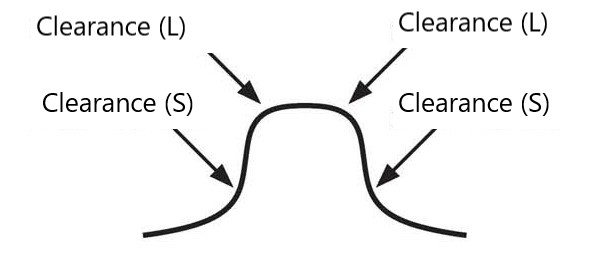

②Burr prevention is carried out in the second process, and by partially changing the clearance, burrs are eliminated.

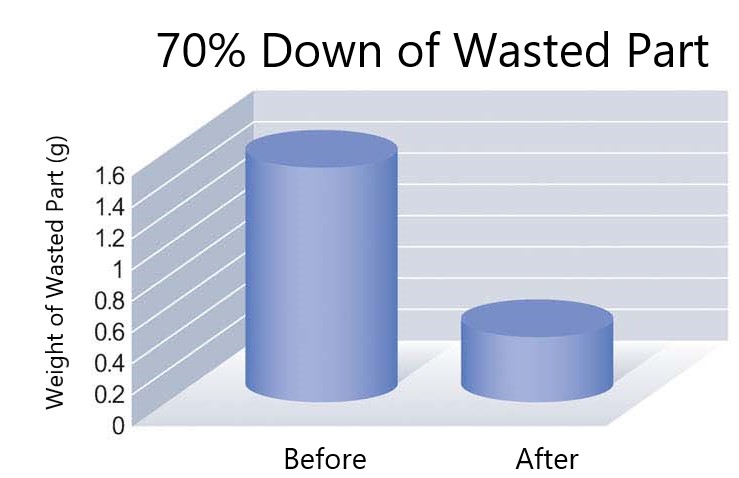

Result

①No post processing (deburring) required ②Better yield (compared to normal broaching) ③High accuracy of the broaching surface