Overhaul

Restoration of functions and precision through total disassembly and all-part checks

From on-site responses to full-scale overhauls at our factory, the corrected precision manufacturing including the frame is carried out by newly produced machining equipment and skilled technicians.

Retrofit

Updating through the addition of automation and new functions

We update important existing machines through the addition of automation, increase in speed, and new functions.

The installation of dedicated functions helps customers create profits.

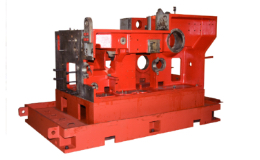

Overhaul – Disassemble

A case of overhaul for AF1513-4 at Asahi Sunac factory in Japan.

Overhaul – Rebuild

A case of overhaul for AF1513-4 at Asahi Sunac factory in Japan.

Retrofit – Jog Drive System

During inching operations(JOG), clockwise and counterclockwise operation is available at a speed of the operators’ discretion using the joystick controller on the control panel. No need to switch the main motor from clockwise to counterclockwise operation enables reduced changeover time and easy transfer finger timing adjustment through inching.

Retrofit – Assist Saver System

The second transfer on the AOT or AT machine slides back and forth, then the blank is inserted into the second die.

This Assist Saver System enables stable production of the short products.

*for AOT series and AT series