PRECISION CLEANING TECHNOLOGY

Precision cleaning technology from the development of atomization technology

Precision cleaning technology is to atomize the cleaning liquid, then atomized cleaning liquid is continuously collided at high speed and high density, and this cleaning mechanism can remove the particle with the collision energy. The contactless and physical cleaning system widely cleans from several microns to nano sized particles.

We will contribute to cleaning process of electronic devices such as flat panels and semiconductors that are getting high definition and high miniaturization.

HPMJ® High pressure micro jet cleaning system

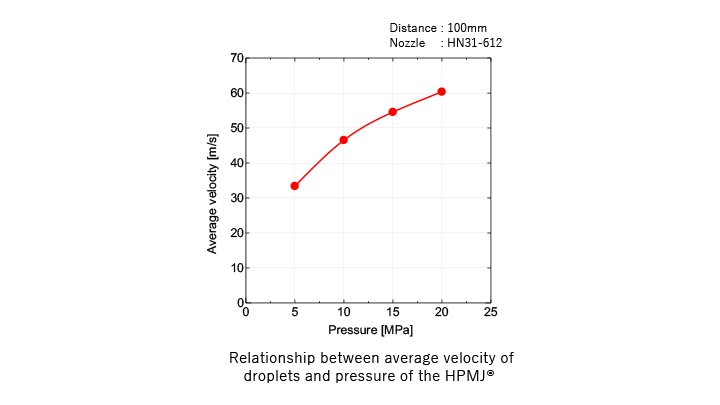

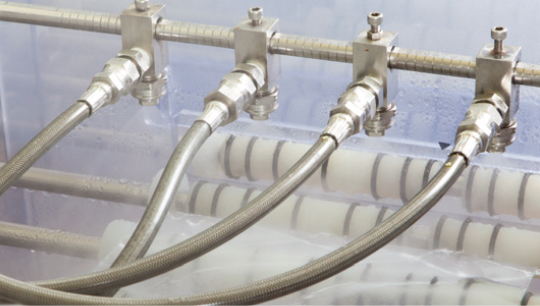

HPMJ® is the physical cleaning system that the cleaning liquid is pumped from the high pressure pump and atomized cleaning liquid is continuously collided at high speed and high density by spray. "HPMJ®" is a registered trademark of Asahi Sunac Co., Ltd., which is registered in Japan, China, the United States, South Korea, Taiwan, Malaysia, and Singapore.

"HPMJ®" is a registered trademark of Asahi Sunac Co., Ltd., which is registered in Japan, China, the United States, South Korea,

Cleaning (Image)

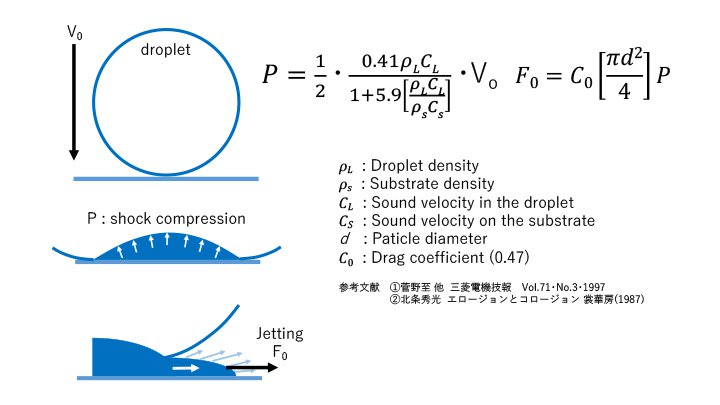

Cleaning mechanism jetting effect

The atomized cleaning liquid jetted from the micro jet nozzle collides with the work at high speed, and the force of the repulsive energy generated there separates the fine particles adhering to the work.

Application examples

| FPD manufacturing process | CF | Initial cleaning, rinse after development |

|---|---|---|

| Array | Initial cleaning, pre-deposition cleaning, cleaning after |

|

| Cell | Cleaning before PI, cleaning after rubbing, cleaning after cutting | |

| Organic EL | Initial cleaning, pre-deposition cleaning |

| Semiconductor cleaning process | Cleaning after slicing, Initial cleaning, laser cutting |

|---|---|

| Solor manufacturing process | Cleaning after slicing, Initial cleaning, laser cutting |

| Other | Cleaning of production process jigs, food industry, medical industry |

High speed plusating jet system

HSPJ® is the physical cleaning system and added the cavitation effect at the pressurized liquid go through the nozzle.Then, more high speed and high density droplets are discharged towards workpiece by the cavitation effect.

* Cavitation effect: Bubble cloud area is efficiently generated by liquid control.

"HSPJ®" is a registered trademark of Asahi Sunac Co., Ltd.that is registered in Japan, China, the United States, South Korea, Taiwan, Malaysia, and Singapore.

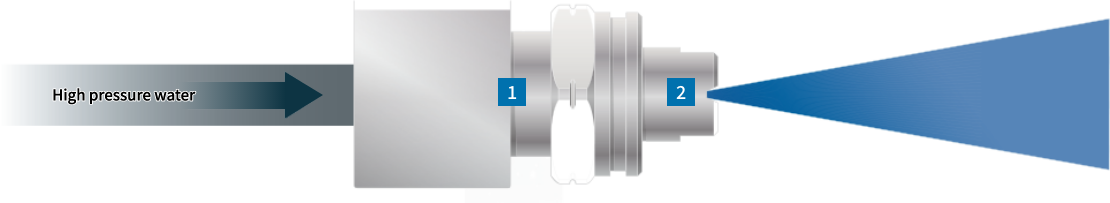

HSPJ mechanism

1Cavitation

It generates periodically bubble clouds.

2HSPJ nozzle

Discharged droplets velocity loss is reduced by smooth conical shape of the inside of the nozzle.

High speed and high density droplets are discharged by HSPJ with cavitation effect, then the droplets are collided continuously to remove microscopic particles on the workpiece.

Please feel free to contact with our division for any questions or concerns you might have about Precision cleaning equipment, Precision spray coating equipment and sensing technologies.