Introduction of SF50 Series Part Formers – Part 2

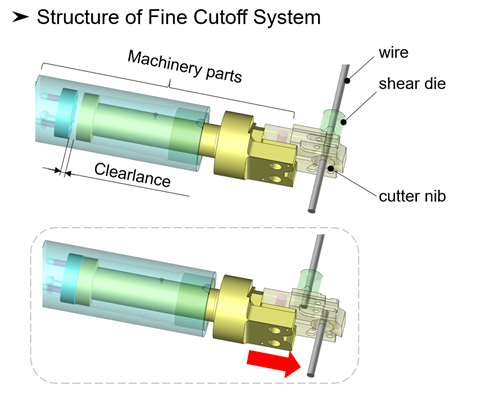

Part 2 of this series introduces the mechanism for cutting materials, Fine Cutoff System.

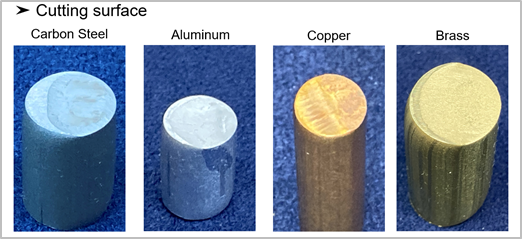

Fine Cutoff System is a cutting mechanism developed to make the cutting surface as smooth as possible. It is possible to cut at a higher speed at the start of cutting by providing a clearance inside the machine part.

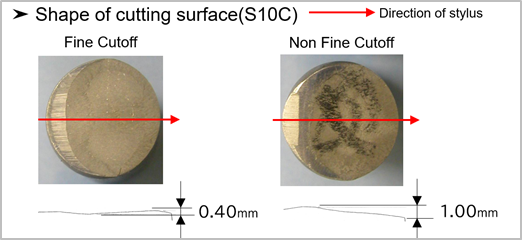

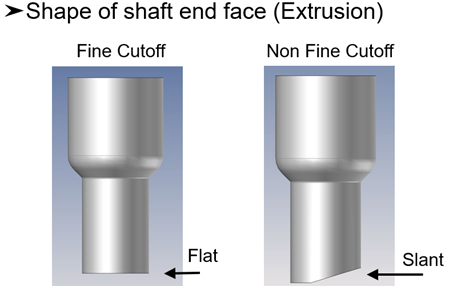

Conventional cutting mechanism cuts materials at a speed from “0”, resulting in a slanted cut surface. However, when cutting with this mechanism, the cutoff surface is nearly flat and smooth.

In conventional cutting, the cutoff surface is often slanted, and the shaft end face after being forged could also remain slanted in an extrusion process. In order to make the shaft end face flat, an end face straightening process is crucial. On the other hand, Fine Cutoff System enables reduction of the end face straightening process because the cutoff surface is nearly flat.

In combination with the Fine Feed System, the weight variation of the cutoff material is reduced by half, which has the effect of improving the dimensional accuracy of the product.

It is also expected the effect of extending die life.

In this issue, we introduced the “Fine Cutoff System” of the SF50 series. In Part 3, we will introduce the “Fine Slide System,” a mechanism that minimizes variation in product accuracy.