Introduction of SF50 Series Part Formers – Part 1

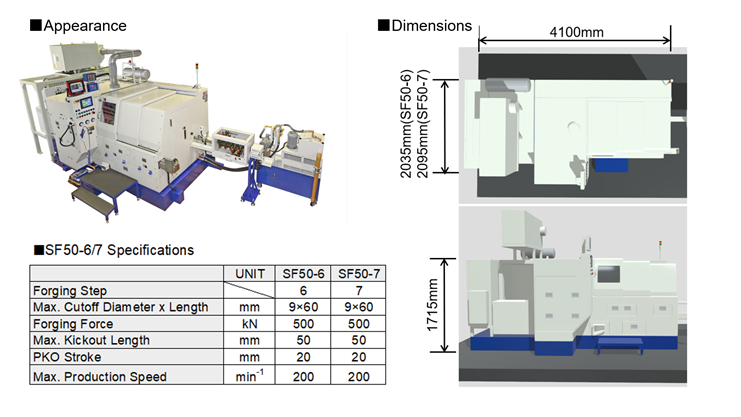

The Part Former SF Series feature three “Fine” functions, including material feeding (Fine Feed System), material cutting (Fine Cuttoff System) and press forming (Fine Slide System), and Universal Transfer System, as well as applied to the smallest size SF50-6/7.

The recent rapid changes in market needs toward a decarbonized society and the growing demand for eco-friendly electronic components, such as electric vehicles, has led to the widespread use of compact part former SF50 that enables highly precise forming of components with complex shapes. (*Photo shows SF50-7)

We introduce the features of SF50-6/7 in series. The first is the “Fine Feed System”.

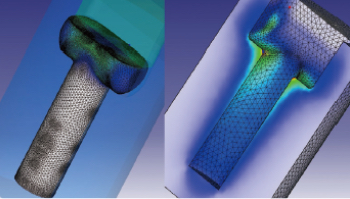

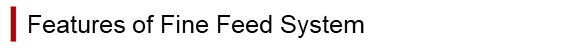

The conventional material feed mechanism clamps the wire material with rollers and feeds it to the cutting process by rotating the rollers. Since the wire material is forced to push against the stopper pin to stop, the cutoff surface and the stopper pin may collide when cutting, resulting in scratches.

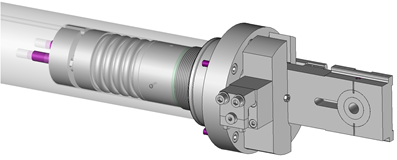

On the other hand, Fine Feed System grasps and feeds the wire material by “grip-and-pass” action, the reciprocating drive of the gripper. The feed length is determined by the movement amount of the gripper by the cam drive, so the movement amount needs to be set and the stroke is measured by the movable distance measuring sensor. Since no load is applied to the wire material, scratches due to the stopper pin are not generated on the cutoff surface, and this method is effective in improving the quality of forging products.

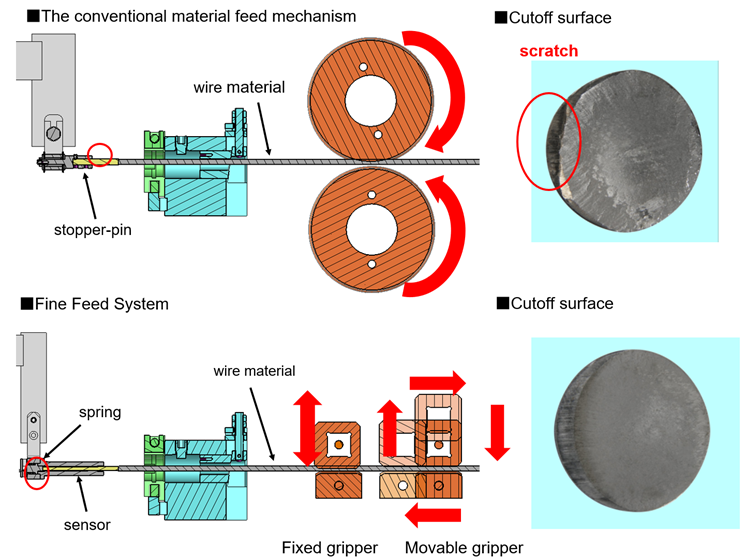

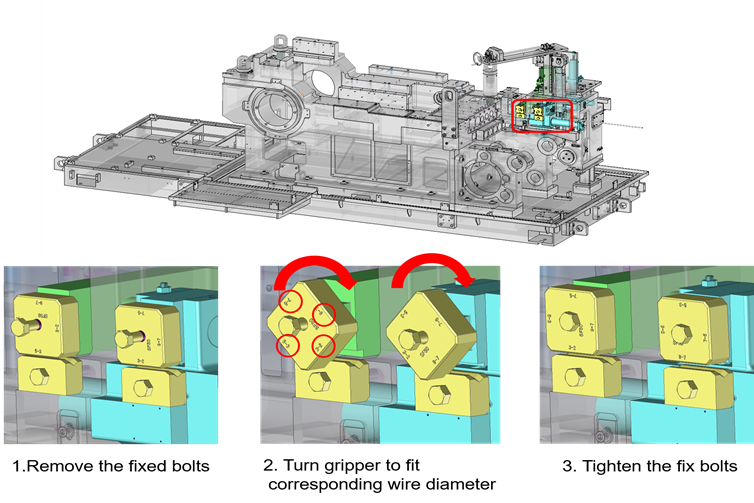

In the conventional setup work of the material feed mechanism, it was necessary to prepare feed rollers that match the wire diameter of the material and perform the replacement work. It was a burden for workers to manually replace heavy load feed rollers. Feed roller replacement is eliminated from SF50-6/7. A method is adopted in which a gripper covering all of the cutting diameters from the maximum to the minimum is rotated according to the wire diameter of the material to select it. It is not only possible to work without a heavy object, but also there is no need to manufacture feed rollers that match each wire diameter.

Part.1 was to introduce SF50-6/7‘s “Fine Feed System.” In Part.2, we will introduce the “Fine Cutoff System”.