Introduction of SF50 Series Part Formers – Part 3

Part 3 of this series introduces the structure of the ram slide.

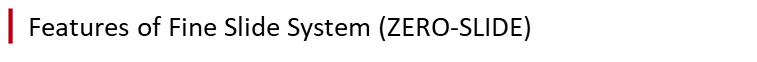

To minimize variation in product accuracy, the clearance of the slide must be minimized. If the clearance of the slide is not appropriate, the die and punch may be off-center due to differences in the forming load at each process during forming. Currently, the center of the punch is adjusted in anticipation of the misalignment to ensure product accuracy, but this adjustment requires a high level of skill from the operator.

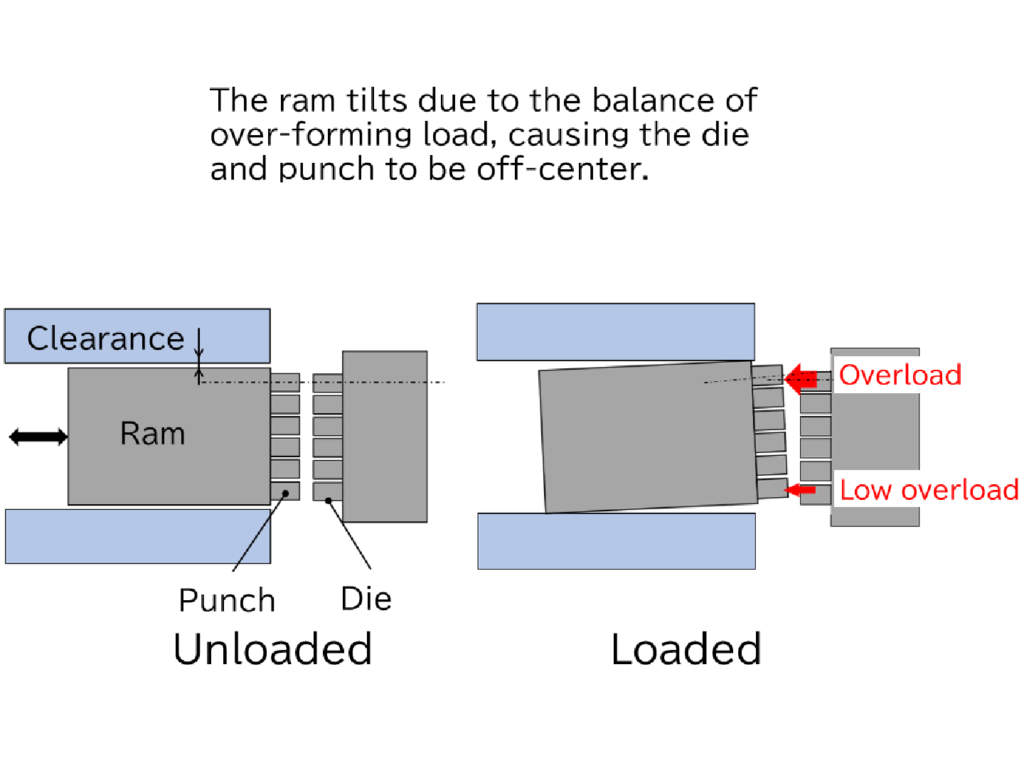

ZERO-SLIDE structure is our original mechanism that achieves “0” clearance at the slide section. In 2011, the ZERO-SLIDE structure was adopted for 500 kN parts formers and more than 30 units have been delivered, and ZERO-SLIDE is currently being expanded to 2000 kN parts formers.

・No need of punch adjustment for product release.

・No more friction between the punch pin and die hole.

In this issue, we introduced the “ZERO-SLIDE” of the SF50 series. In Part 4, we will introduce the “Universal Transfer System”, a mechanism for transporting workpieces.