CTC|COATING TECHNOLOGY CENTER

It suggests the ideal coating system for clients through research experiments, software development service, etc.

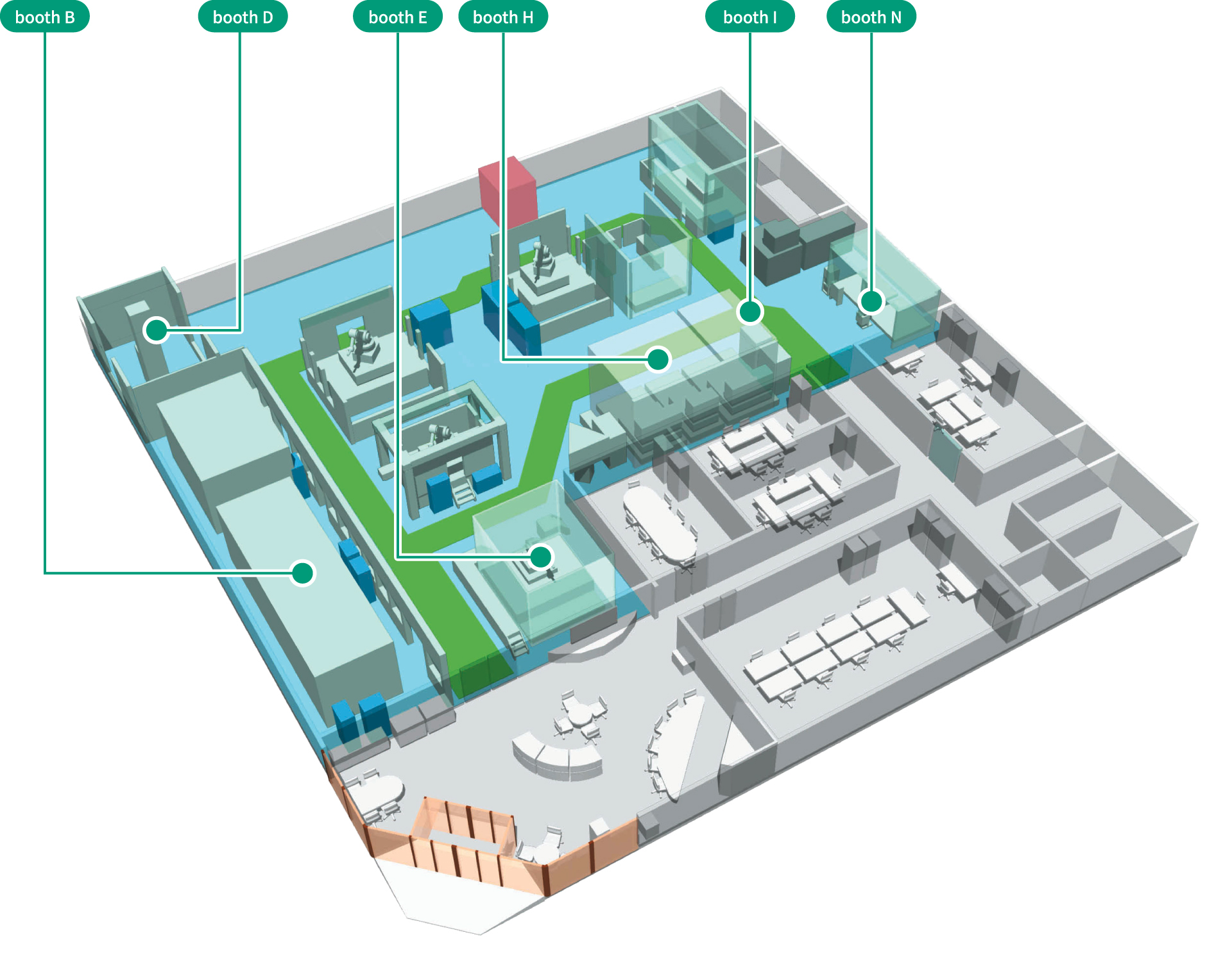

The Coating Technology Center (CTC) was established in 1979, at the forefront of the industry, as a place bringing together coating technologies, experimental installations, technological development functions, and technical information systems.The CTC provides cutting-edge coating equipment/systems that are compatible with eco-friendly paints, such as powder, water-based, and two-component paints. It also offers devices for replicating the coating environment (temperature, humidity, etc.) to be used by clients, and always suggests the ideal coating system for clients through research experiments, software development service, etc.

- booth B

- booth C

Automatic Powder Coating system

Deliberation and suggestions can be provided to the client to conclude what the ideal powder coating system would be for any situation.

- booth D

Vertical Reciprocator

Investigation and suggestions can be provided the ideal coating system to the client using a high-performance reciprocator.

- booth E

- booth G

- booth K

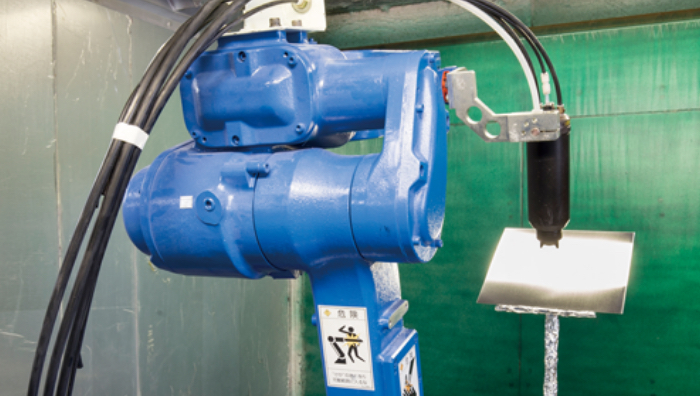

Robot Booth

Investigation and suggestions can be provided the ideal coating system to the client using various robots.

- booth H

Hand spray booth

Suggestions can be provided the ideal combination of spraysetting and coating equipment.

- booth I

- booth F

Constant Temperature and Humidity Experimentation Booth

It is possible to replicate various coating environments such as the temperature and humidity.

- booth N

Basic experiment booth

Suggestions can be provided the ideal combination of spraysetting and coating equipment.

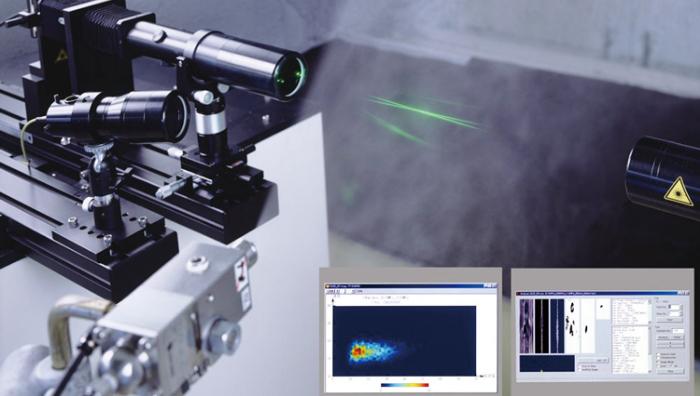

Shadow Drop Particle Analysis Equipment

Analyze coating particles and coating film using various latest measurement equipments.

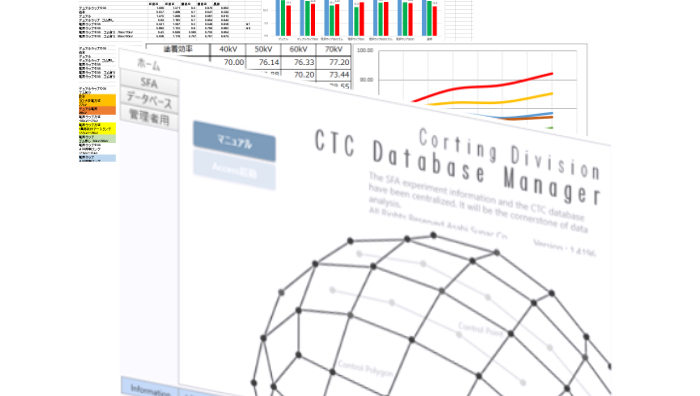

Information Service

Information is gathered and analyzed, including results from coating experiments and software development.

Training and Development Service

At Robot School, educational programs are fashioned and carried out according to individual customer demands, ranging from device/systems operations to maintenance.

No.1 information center in eastern Japan

Tokyo Technology Center (TTC) is a sales facility of Asahi Sunac East Japan with a site area of 1860㎡, that solves customers' coating problems by the latest painting equipment and systems. We will enrich software technology information such as UTS gallery and factory reportage search, and aim to be a painting technology center that is used by many customers as the best information transmission base in eastern Japan.

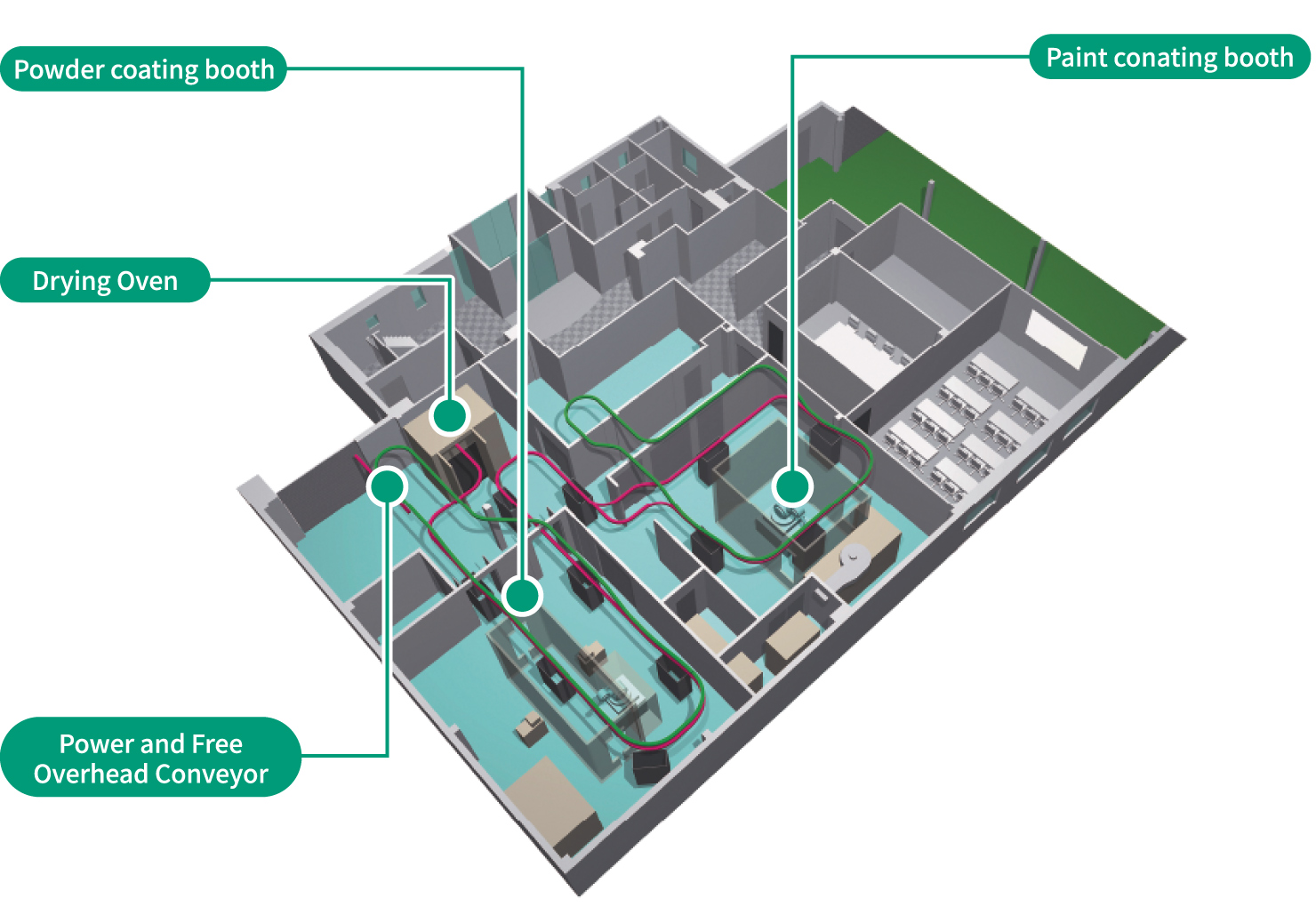

Powder coating booth

Take a look at the powder coating that uses a new dual electric field technorogy to achieve a high level finishing.

Paint conating booth

You can test liquid electrostatic automatic painting using a robot. It can be used for painting samples and pre-verification before system introduction. At this painting booth, we will solve your coating problems together.

Drying Oven

It is possible to prevent the adhesion of dust and stuff,

because the work can be automatically carried into the drying oven while it is on the conveyor.

Power and Free Overhead Conveyor

Two conveyors are installed in the laboratory. Work can be easily and safely transported and worked in both liquid coating booths and powder coating booths using a long conveyor that connects to the entire laboratory. Combined work is also possible.

Please feel free to contact us for any inquiries or questions regarding the coating equipment and engineering.

Please feel free to contact us for any consultations or questions related to the services of Coating Equipment Division.