CASE STUDY

We are posting a factory report what was published “COATING TECHNOLOGY” (coating specialty magazine by COTEC CORPORATION).

Search Results: 108

No.452 / February,2026

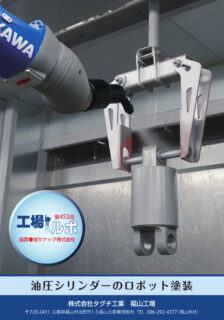

Automated Robotic Coating for Hydraulic Cylinders ⁂ ⁂

- Client Name:

- Taguchi Industrial Co., Ltd.

- Used paint:

- Liquid paint

Introduction:To resolve quality variation, booth contamination, complex color changes, and low productivity caused by hand spray coating, the company upgraded to an automated coating system.

Benefits

1. By using an automatic spray gun with an angled compact head and optimized coating robot paths, teaching was simplified,which reduced overspray, lowered paint consumption, and improved productivity.

2. The introduction of a color change valve enabled one-touch color switching, eliminating complicated color change operations.

No.451 / January,2026

Powder Coating System for LP Gas Cylinders ⁂

- Client Name:

- BFG Engineering Co., Ltd.

- Used paint:

- Powder paint

Introduction: To address rising paint usage, reduced recovery efficiency, and worsening work conditions caused by aging coating equipment, the company introduced a new powder coating system, featuring automatic coating guns.

Benefits

1. The new system achieved higher coating efficiency and excellent coverage, improving coating productivity by 25%.

2. With the improvement of the work environment by reducing overspray, the enhanced parts supply system and after-sales service have received high praise.

No.450 / December,2025

Electrostatic Heat-Resistant Coating for Microwave Oven Grill Frames ⁂

- Client Name:

- FUJIO Co., Ltd.

- Used paint:

- Liquid paint

Introduction:To address aging equipment and improve coating quality and labor efficiency, the company renewed automatic spray guns on two coating lines.

Benefits

1. Paint consumption and touch-up work were significantly reduced, increasing correction-free production and improving process efficiency.

2. Uniform, high-quality finishes were consistently achieved, contributing to labor savings.

3. The upgrade of the automatic spray guns delivered measurable gains in quality, productivity, and cost efficiency with minimal investment.

No.449 / October,2025

Powder Coating for Air Conditioner Outdoor Unit Panels

- Client Name:

- Shimura-tk Co., Ltd.

- Used paint:

- Powder paint

Introduction: To address reduced coating efficiency from aging equipment and the increased workload on operators due to touch-up work, the company introduced new powder coating equipment.

Benefits

1. Paint usage was reduced by 50% and automatic powder coating guns doubled panel productivity while boosting output of other components by 30%.

2. Touch-up work was reduced to less than half, allowing a reduction in personnel from 2 to 1 and achieving significant labor savings.

No.448 / September,2025

Powder Coating of Metal Products ⁂ ⁂ ⁂ ⁂ ⁂ ⁂ ⁂

- Client Name:

- Fukushima enamel Industrial Incorporated company

- Used paint:

- Powder paint

Introduction: The company provides solvent and powder coating services for general metals and aluminum. Traditionally, powder coating had been applied manually in the same booth used for solvent coating. However, challenges such as coating quality issues, poor working conditions caused by a drying furnace installed directly above the booth, and concerns over potential labor shortages prompted the company to introduce a painting robot.

Benefits:

1. By establishing a dedicated powder coating line, the company achieved full automation without manual correction, resulting in improved coating quality.

2. The high transfer efficiency of the coating guns allowed for increased conveyor speed, which enhanced productivity and reduced coating material usage by approximately 20%.

No.447 / August,2025

Electrostatic Coating of Die-Cast Products ⁂ ⁂ ⁂ ⁂ ⁂

- Client Name:

- HOKURIKU seiden CO., Ltd.

- Used paint:

- Liquid paint

Introduction To resolve issues caused by aging coating guns on its two-component coating line, such as declining quality, reduced productivity, and environmental concerns, the company upgraded its coating equipment and facilities.

Benefits

1. The use of base resin and hardener, along with the amount of waste generated, was reduced by 15%.

2. Improvements in coating efficiency enabled an increase in line speed by 0.2 m/min.

3. The combination of highly efficient automatic coating guns and a multi-color two-component mixing system capable of high-quality coating created a synergistic effect, achieving both cost reduction and productivity improvement.

No.446 / July,2025

Powder Coating of Pole Air Switch (PAS) Cases ⁂ ⁂ ⁂

- Client Name:

- Togami Metalix Co., Ltd.

- Used paint:

- Powder paint

Introduction:To overcome the challenges of aging equipment and limited production capacity, the company has launched a new factory and upgraded its coating line.

Benefits:

1. Production capacity has increased 1.5 times compared to the previous system.

2. By recovering and reusing paint, paint usage has been reduced by 10%.

3. Future improvement, such as precise touch-up identification, is expected to further improvements in productivity, reduced paint waste, and decreased correction work.

No.445 / June,2025

Powder Coating of High-Pressure Gas Cylinders ⁂

- Client Name:

- Nagoya Nissan Co., Ltd.

- Used paint:

- Powder paint

Introduction : In response to environmental concerns and the need to improve work efficiency, the company introduced an eco-friendly powder coating system and revamped its coating line.

Benefits :

1. Improved work efficiency by eliminating the need for color changes through the use of dedicated booths for each paint color.

2. Enhanced the working environment by reducing paint overspray outside the booths.

3. Increased productivity with a uniquely designed booth and high-efficiency coating gun.

No.444 / April,2025

Robot Coating of Breaker Boxes for Semiconductor Equipment

- Client Name:

- Motohashi MFG Co., Ltd. Tohoku Factory

- Used paint:

- Liquid paint

Introduction: The company has expanded its factory and introduced automatic systems in anticipation of rising demand in the booming semiconductor industry. The robot coating system was installed to replace the traditional manual spray coating process.

Benefits:

1. By improving the efficiency of coating guns, it has ensured consistent product quality and greatly improved productivity.

2. Addressed labor shortages and improved employee well-being through automation.

No.443 / March,2025

Powder coating of metal products

- Client Name:

- Kitamura Industrial Painting Co., Ltd. Morimoto Factory

- Used paint:

- Powder paint

Introduction:Due to concerns about a future labor shortage, the manual spray booth was renovated, and an automatic electrostatic coating system was installed to reduce manpower.

Benefits:

1. Correction work that previously required two workers can now be handled by one.

2. Established a system that allows us to maintain productivity even with reduced staffing, while still meeting customers' demands.

Please feel free to contact us for any inquiries or questions regarding the coating equipment and engineering.

Please feel free to contact us for any consultations or questions related to the services of Coating Equipment Division.