|

Model |

ACW1200EXL |

ACW1200EXH |

|---|---|---|

|

Mix ratio |

1:1~12:1(MAX30:1)※1 |

|

| Mix precision | +/-5% or less ※2 | |

| Compatible liquids | One type of base resin, one type of hardening agent | |

|

Compatible viscosity (before mix) |

25 to 300mPa∙s ※2 |

25~3,000mPa・s ※2 |

|

Max. discharge correspondence |

100 to 1,000mL/min ※3 |

200~2,000mL/min ※3 |

|

Supplied air pressure |

0.4 to 0.7MPa and over | |

| Remarks | For low pressure | For high pressure |

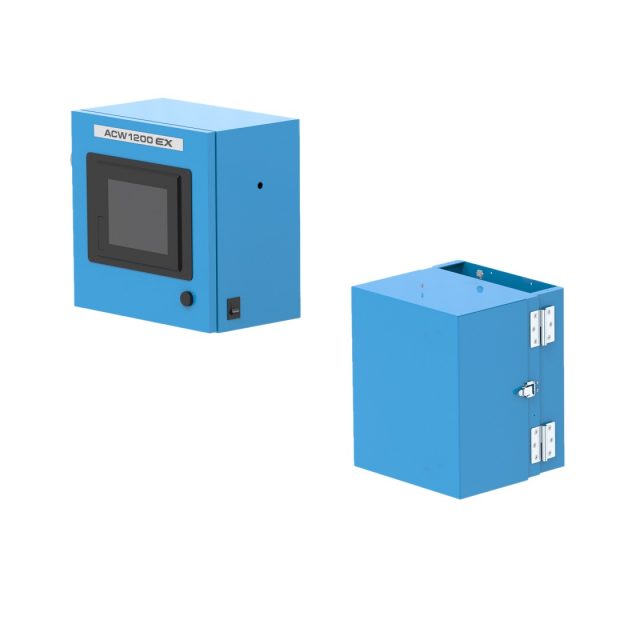

■ Control Unit

|

Operations environment |

Temperature 0 to +40℃ / Humidity 10 to 80% (without condensation) |

|---|---|

| Operations atmosphere | Avoid exposure to corrosive gases, grit and dust, steam, dripping water, or direct sunlight |

| Transport storage | Temperature 10 to +50℃ / Humidity 10 to 90% (without condensation) |

|

Power supply voltage |

AC100V ±10% 50/60Hz |

| Power consumption | 3A |

| Dimensions | 400W×400H×250D mm ※4 |

| Mass | 30kg |

| Explosion-proof compatible |

Non-explosion proof |

■Mixing Unit

|

Low pressure specs |

High pressure specs | |

|

Paint path max. pressure resistance |

1.5MPa ※5 | 25MPa |

| Supplied paint pressure | For low-pressure specs, more than 3 times the pressure needed for discharge is necessary. ※5 | |

| Wetted material | Tungsten carbide, stainless steel, Teflon, polyester | |

| Suitable paint |

Solvent two-component urethane and epoxy paints for top coating ※6 |

|

| Dimensions |

350W×375H×300D mm |

|

| Mass | 30kg | |

| Explosion-proof compatible | Essential safety explosion-proof specs (flow meter, solenoid valve, handy control panel) ※7 | |

| Remarks | For low pressure | For high pressure |

■Standard structure

| ACW1200EXL | ACW1200EXH | ||

| Mixing Unit | Mixing valve | ● | ● |

| Flow meter | ● | ● | |

| Cleaning valve assembly | ● | ● | |

| Drain valve | ● | ● | |

| Box | ● | ● | |

| Essential safety explosion-proof solenoid valve (for mixing valve) | ● | ● | |

| Control unit |

ACW controller

|

● | ● |

|

Buzzer

|

● | ● | |

|

Lamp (red)

|

● | ● | |

|

Power Switch

|

● | ● | |

|

Non-explosion proof solenoid valve (for cleaning valve assembly, drain valve)

|

● | ● | |