PRODUCTS

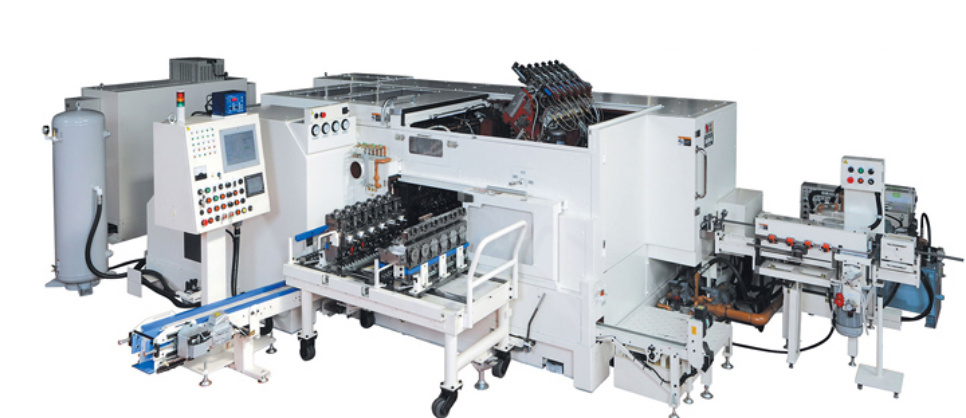

SGF

Downsizing of Equipment by Phase Difference Ram Configuration

By making the ram a split structure, the peak load is dispersed to reduce the allowable load, achieving the frame weight to become one half and the other drive system to be downsized.

Horizon Installer

Die set is exchanged through the window located at the side face of the frame, reducing the setup time.

Die block and punch block are exchanged through the window located at the side of machine’s main frame.

Reduction of Product Run-out due to Influence of Heat

By dividing the die block into processes and devising the reference surface of the die block, thermal expansion due to processing heat is suppressed and time-dependent change of the product is controlled.

| Item | SGF100 | SGF150 | SGF250 |

|---|---|---|---|

| Forging Step | 6 | 6 | 6 |

| Max. Cutting Dia. (mm) | 15×25 | 15×45 | 20×150 |

| KO (mm) | 50 | 50 | 180 |

| Production Speed (spm) | 90 | 90 | 80 |

Please feel free to contact us for any inquiries or questions regarding the forging machines and tooling.