PRODUCTS

Coating

Spray Nozzle

Rotary atomizing system

Rotary atomizing nozzle ASG-10

ASG-10

This nozzle can control the spray droplets size and velocity individually for forming optimal film thickness.

Specifications

| Model | ASG-10 |

|---|---|

| Maximum compressed air consumption | 570NL/min |

| Maximum discharge rate | 5-100 [ml/min] |

| Droplet diameter | 10-30 [μm] |

| Droplet velocity | 10-20 [m/sec] |

| Spray pattern | 25-70mm |

| Weight | 800g |

Spray Nozzle

Low pressure atomizing system

Low pressure atomizing nozzle AGB50N TFC10

AGB50N

TFC10

This nozzle atomizes stably almost same size of spray droplets in the spray pattern. To make the dry speed of the coating film uniform for preventing uneven film thickness.

Specifications

| Model | AGB50N | TFC10 |

|---|---|---|

| Maximum compressed air consumption | 160NL/min | 30NL/min |

| Maximum discharge rate | 5-50 [ml/min] | 2-20 [ml/min] |

| Droplet diameter | 10-30 [μm] | 10-30 [μm] |

| Droplet velocity | 20-70 [m/sec] | 20-70 [m/sec] |

| Spray pattern | 25-70mm [WD100mm] | 25-30mm [WD50mm] |

| Weight | 430g | 150g |

Spray Nozzle

Electrostatically extracted system

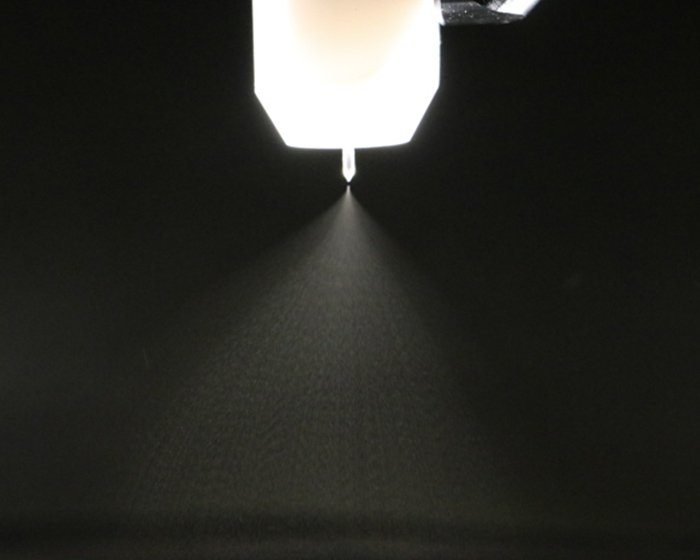

Electrostatically Extracted Nozzle

AES100

This nozzle forms to high precision coating film by high atomizing and micro discharging rate.

In addition, since no air is used for atomization, a stable film-forming environment is ensured.

Specifications

| Model | AES100 |

|---|---|

| Maximum compressed air consumption | ー |

| Maximum discharge rate | 0.01-1[ml/min] |

| Droplet diameter | 1-8[μm] |

| Droplet velocity | 1-5[m/sec] |

| Spray pattern | ー |

| Weight | 80g |

Suplying device

Automatic filling syringe pump

PCF601

PCF601

This pump is the discharging and the automatic filling repeatedly. It has high discharging rate accuracy and can change the flow rate during discharging.

Specifications

| Model | PCF601 |

|---|---|

| Power | 90VA (AC adapter rating) |

| Diversion control range | 0.01-30.00mL/min(at 10mL syringe) |

| Drive system | 32kgf |

| Number of syringe | 1 pc |

| Capacity of syringe | 1, 2.5, 5, 10, and 25mL * Syringes are not included with the pump, and must be ordered separately. |

| Unit dimensions | 150mm×155mm×250mm |

| Weight | 2.9㎏(AC adapter weight not included) |

| Operating temperature range | 10-85%RH(But, the thing without dew condensation) |

| Operating temperature range | 0-40℃(But, the thing without dew condensation) |

| Viscosity of Fluid Used | –100mPa・s |

| Suction Lift | Max. 1.5 m |

| Connection Diameter | Suction:Φ4×2.5mm Disgorge:Φ3×1mm |

| Discharge reproduction accuracy(Exit side opening) | Within 2%(10mL syringe Fluid used: at pure water) |

* They aren't waterproofing and explosion-proof construction, so you can't use under the environment that a drop of water hangs and the flammable gas atmosphere.

* This product isn't explosion-proof construction. It can't be used in danger zone Zone 0-2 set as JIC C 60079-10.

Suplying device

Gear pump

GPN series

GPN 050/015

GPN 050/015 Package spec.

"Wetted parts of this gear pump is high-precision processing and special surface treatment. It is possible to dismantle and reassembly for cleaning. The fluctuation in the discharge amount is limited and it is quantitative. It is capable of controlling the flow rate by itself by attaching a control unit as a package specification. In addition, the structure makes it easy to disassemble and clean the gear pump."

Specifications

| Model | GPN050 | GPN015 |

|---|---|---|

| the discharge rate | 0.5mL/rev | 0.15mL/rev |

| Viscosity of Fluid Used | -100mmPa・s | -100mmPa・s |

| Regular Rotation Speed | 10‐100rpm | 10‐100rpm |

| Connection Diameter | Rc1/8 | Rc1/8 |

| Discharge Accuracy (Discharge Side Opened) | Within ± 2% | Within ± 3% |

| Material of Liquid Contact Surface | SUS + Special surface treatment | SUS + Special surface treatment |

| Maximum Fluid Temperature | 50℃ | 50℃ |

* Discharge accuracy measurement conditions: Fluid used: IPA, Viscosity: 2.4 mPa·s (20℃), Suction/Discharge pressure: 3 kPa

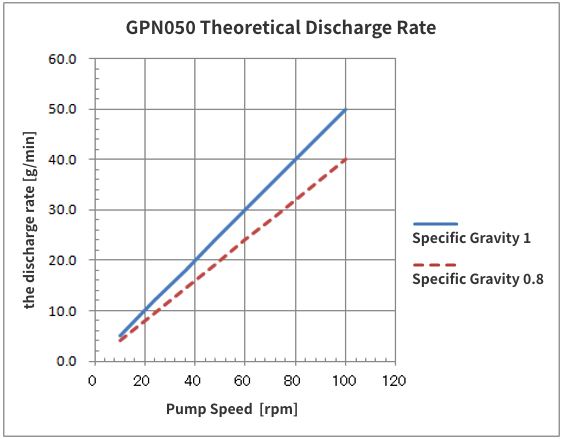

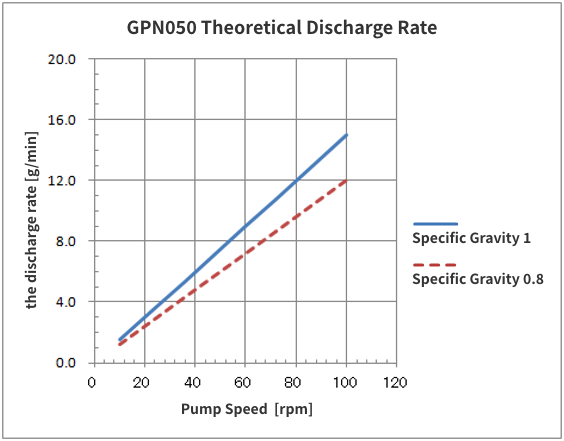

NOTE: Pump Rotation Speed and Theoretical Discharge Amount

This is the theoretical discharge amount calculated from the number of revolutions of the pump and the discharge amount per rotation.

The actual discharge rate depends on the piping resistance,

specific gravity of the liquid, viscosity or etc and it is 2 - 20% lower.

Suplying device

The double syringe system

PCF series

PCF-5/10/20/50/100

The PCF series is a pump that enables pulsation-free quantitative injection without using an accumulator. In addition, the structure that does not use the inlet valve and discharge valve eliminates troubles caused by the valve and enables a stable discharge rate.

Specifications

| Model | PCF-5 | PCF-10 | PCF-20 | PCF-50 | PCF-100 |

|---|---|---|---|---|---|

| the discharge rate *1 | 1-5mL/min | 1-10mL/min | 2-20mL/min | 5-50mL/min | 10-100mL/min *3 |

| Maximum discharge pressure | 0.3Mpa | 0.3Mpa | 0.3Mpa | 0.3Mpa | 0.3Mpa |

| Piston Diameter | 6Φ | 6Φ | 6Φ | 10Φ | 10Φ |

| Stroke | 8mm | 8mm | 8mm | 8mm | 8mm |

| Motor | 200V 3-phase 25W Rating 0.3A Indoor Type | 200V 3-phase 25W Rating 0.3A Indoor Type | 200V 3-phase 25W Rating 0.3A Indoor Type | 200V 3-phase 25W Rating 0.3A Indoor Type | 200V 3-phase 25W Rating 0.3A Indoor Type |

| Gear Ratio | 150:1 | 75:1 | 36:1 | 36:1 | 30:1 |

| Standard Connection | Φ4 × Φ2 tube | Φ4 × Φ2 tube | Φ4 × Φ2 tube | Φ6 × Φ4 tube | Φ6 × Φ4 tube |

| Maximum Suction Lift | 1m | 1m | 1m | 1m | 1m |

| Approximate Weight | Approx. 12㎏ *2 | Approx. 12㎏ *2 | Approx. 12㎏ *2 | Approx. 12㎏ *2 | Approx. 12㎏ *2 |

* 1 The discharge amount is the standard value at a discharge pressure of 0.3 MPa. (Normal temperature / Clean Water)

* 2 Approximate weight is the value using POM.

* 3 The control range of PCF-100: 9 to 90Hz. (Other models are 6-60Hz.)

Suplying device

Electric diaphragm pump

Since there is no sliding part in the wetted section, it is strong against friction and has excellent durability. Also, there is little pulsation.

Specifications

| Max. Discharge Rate | 0.025L/min |

|---|---|

| Maximum Working Pressure | 1.5MPa |

| Frequency Setting Range | 6-60Hz |

| Viscosity of Fluid Used | 50 Pa·s or less |

| Discharge Accuracy (Discharge Side Opened) | Within ± 2% |

We will propose the supply system like a pressurized tank suitable for each coating material.

Please feel free to contact with our division for any questions or concerns you might have about Precision cleaning equipment, Precision spray coating equipment and sensing technologies.