PRODUCTS

Liquid automatic coating gun

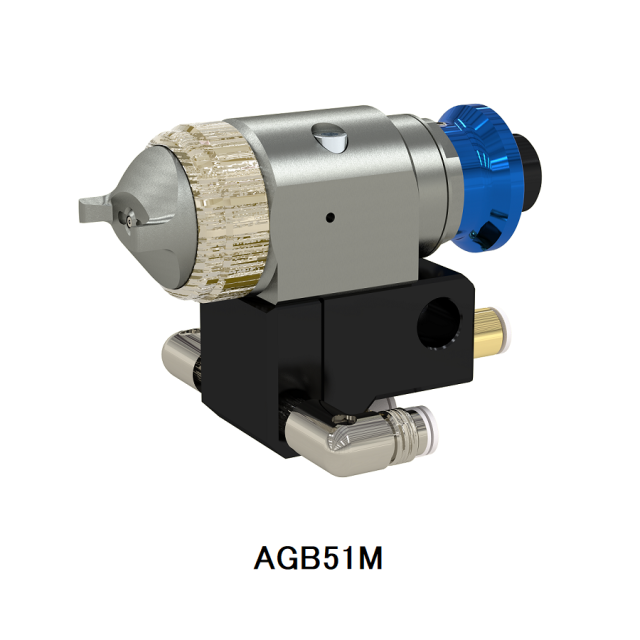

Micro Coat Air Spray Automatic Gun: Pearl Gun AGB50(M)/Low-pressure Air Spray Automatic Gun: Microace AGB51(M)

AGB50/51

Ideal for high-grade thin-film pearl coating with metallic or pearl paints./Low-pressure air atomization provides both a high transfer efficiency and uniform film coating quality.

-

Consistent paint transfer results

A newly-developed nozzle and air cap combination provide a high rate of paint transfer, contributing to a reduction in

paint costs.

-

Remarkable paint film quality

A newly-designed, coaxial nozzle offers uniform paint film quality with excellent atomization.

-

Lower running costs

A newly-developed needle seat structure improves durability when switching the spray mechanism ON/OFF,

contributing to a reduction in running costs.

-

Compact, light-weight design

A 10% reduction in length and 30% reduction in weight compared to previous models provide a compact, light-weight

design. Multiple guns can easily be equipped to a single robot, contributing to an increase in productivity.

-

Specialized nozzle

This standard-equipped nozzle’s rate of paint transfer is about 10% better than former models.

| Product name | Pearl gun | Micro Ace | ||

| Model | AGB50 | AGB50M | AGB51 | AGB51M |

| Max. fluid pressure | 0.6MPa | 0.6MPa | ||

| Max. air pressure | 0.6MPa | 0.6MPa | ||

| Dimensions (L x W x H) | 119×44×91mm | 114×96×92mm | 119×44×91mm | 114×96×92mm |

| Mass | 430g | 650g | 430g | 650g |

| Nozzle | φ1.0 | φ1.1 | ||

| Air cap |

HN400A (sold separately)

|

Select from HN600A, HN800A (sold separately)

|

||

| Fluid outlet diameter | IN OUT Rc1/8 | IN OUT Rc1/8 | ||

| Air hatch | φ8-6mm | φ8-6mm | ||

| Structure/features | For metallic pearl coating | Removal manifold type | - | Removal manifold type |

Note) Make sure to purchase air cap separately.

No.430

Feb., 2024

Powder coating for Water Supply and Sewerage Valves

- Used paint:

- Powder paint

Learn more

Introduction : Powder coating has been introduced for general-purpose valves to prevent rust. The earthquake-resistant valves used solvent coating applied by hand spray, but due to the worsening of the working environment, heavy workload on workers, increased demand and a growing environmental awareness, an automated water-based coating system was introduced. Powder coating of general-purpose valves has reduced paint usage by 10 to 20%. In the automation of water-based coating, the number of line-workers was decreased from 7 to 1, which greatly reduced the manpower and workload.

Return to overview

No.418

Aug., 2022

Electrostatic and Robotic coating of Optical, Medical and Communication Equipment

- Used paint:

- Liquid paint

Learn more

Introduction : The company involves the coating of medical / communications equipment, primarily optical equipment such as cameras. Previously, all non-optical instruments were coated manually, leading to limited productivity. To address this issue, the latest system has been introduced, incorporating robotic assistance.

Benefits : The implementation of the new system resulted in a significant productivity increase, allowing for the coating of 150 to 200 units daily, compared to the previous limitation of 50 units. Robotic assistance has relieved workers of burdensome tasks, such as pre-correction, leading to a reduction in paint usage by approximately 25% per piece compared to manual spraying.

Return to overview

No.415

May., 2022

Repair painting for storage panel materials by robot

- Used paint:

- Liquid paint,Powder paint

Learn more

Purpose of introduction : Painting defects such as uneven surface occurs in the hand spray process.

To reduce the defect rate and save labor, a robot has been introduced.

Benefit : The synergistic effect of the robot and the spray gun with high transfer efficiency has greatly improved the quality of the coating film.

Defect occurrence reduced by 40%, paint consumption and paint waste reduced by 10%. It has also significantly reduced the time and cost of repainting.

Return to overview

Series Mutual Documents

PDF(703.87 KB)

Please feel free to contact us for any inquiries or questions regarding the coating equipment and engineering.

Please feel free to contact us for any consultations or questions related to the services of Coating Equipment Division.