PRODUCTS

High-quality finish

New nozzle design provides consistent spray pattern for a beautiful finish, using less paint.

Ample variations

Three types of air caps to choose from for specific paints and jobs, to meet a wide range of coating conditions.

High durability

Careful analysis of the bellows seal paint valve’s shape and internal structure make it remarkably durable and easy to

clean.

Easy maintenance

The gun’s simple part assembly makes it easy to disassemble and reassemble.

High reliability

Body crafted with special resin for remarkable, high-intensity electrical properties and improved reliability.

| Product name | SungunⅢ | |||

|---|---|---|---|---|

| Model | EAB500 | |||

| Max. fluid pressure | 0.6MPa | |||

| Max. air pressure | 0.6MPa | |||

| Highest applied voltage | DC-90kV | |||

| Dimensions (φ×L) | φ99×330mm | |||

| Mass | 2.7kg | |||

| Air cap set |

Select from HN400,HN600,HN800 (sold separately) |

|||

| Fluid outlet diameter | Our company exclusive paint hose (sold separately) | |||

| Air hatch | φ8-φ6mm, φ6-φ4mm | |||

| Electrostatic Controller | BPS290 (sold separately) | |||

| Structure/features | For solvent paint For reciprocator / fixed Embedded trigger valve specs |

|||

Note) Make sure to purchase air cap set, paint hatch hose, and electrostatic controller separately.

No.442

Feb., 2025

Electrostatic coating of building materials

- Used paint:

- Liquid paint

Learn more

Introduction : Due to the aging of the automatic coating system for topcoat, the reciprocating and automatic spray guns were updated.

Benefits :

1. The coating quality has improved significantly.

2. The high coating efficiency of the automatic spray gun improved productivity and reduced paint usage by 10%.

3. Corrective coating and maintenance work have been significantly improved, reducing the burden on workers.

4. By maximizing the spray gun's performance, it is expected that paint usage will be further reduced.

Return to overview

No.441

Jan., 2025

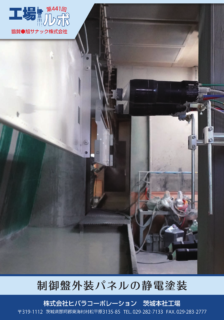

Electrostatic coating of controller exterior panel

- Used paint:

- Liquid paint

Learn more

Introduction : Improving workability and productivity was a challenge.

Benefits : Color changes were done by inserting and removing the paint hose because there was only one paint route. By replacing it with a reciprocator featuring independent left and right control and a two-component coating system, it was possible to secure a separate paint route for each. It is expected that the complicated color change process will be significantly simplified and productivity will nearly double.

Return to overview

No.439

Nov., 2024

Electrostatic coating of architectural hardware

- Used paint:

- Liquid paint

Learn more

Introduction : Introduced the hand spray coating for the undercoat and an automated system for the topcoat. Due to the contribution of the automated system to improved productivity and stable coating quality, the same system was introduced for the undercoat one year later.

Benefits :

1. The amount of work per hanger has increased, improving productivity by 1.5 times.

2. Paint usage was reduced by 10%.

3. Automation has reduced the number of workers required and ensured 100% compliance with the standard film thickness.

Return to overview

Series Mutual Documents

PDF(410.92 KB)

Please feel free to contact us for any inquiries or questions regarding the coating equipment and engineering.

Please feel free to contact us for any consultations or questions related to the services of Coating Equipment Division.