PRODUCTS

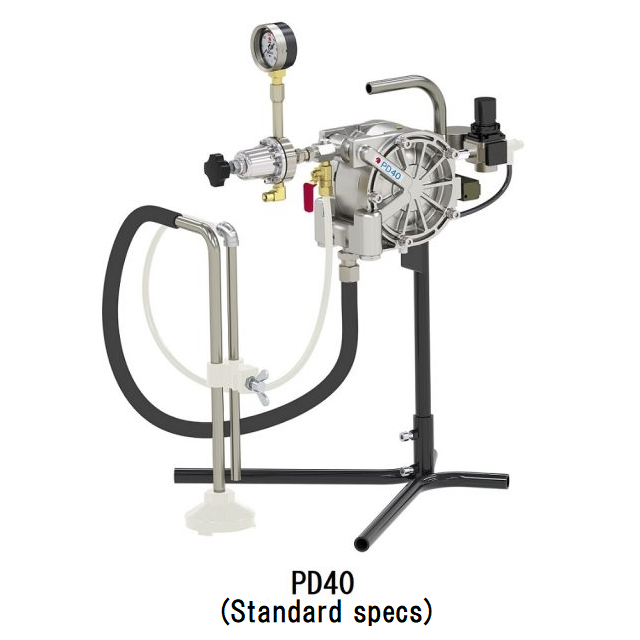

- Diaphragm pump prevents paint leaks due to packing wear, enabling highly-stable coating.

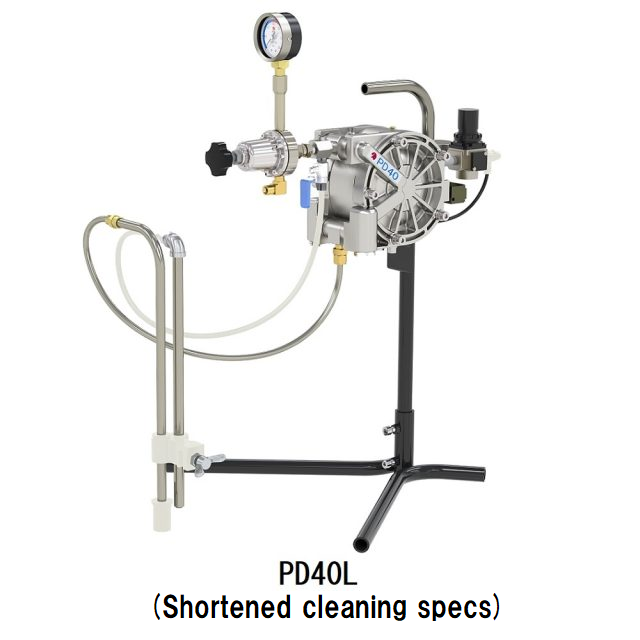

- Paint retention parts have been greatly reduced for easy solvent cleaning during color change, while paint waste and

VOC emissions are significantly reduced.

- The flange is coated with fluorine resin, making it even easier to clean than previous models.(PD40・40L)

- A small bore suction hose allows you to use paint and solvent without waste, and makes it remarkably easy to clean.

(PD40L)

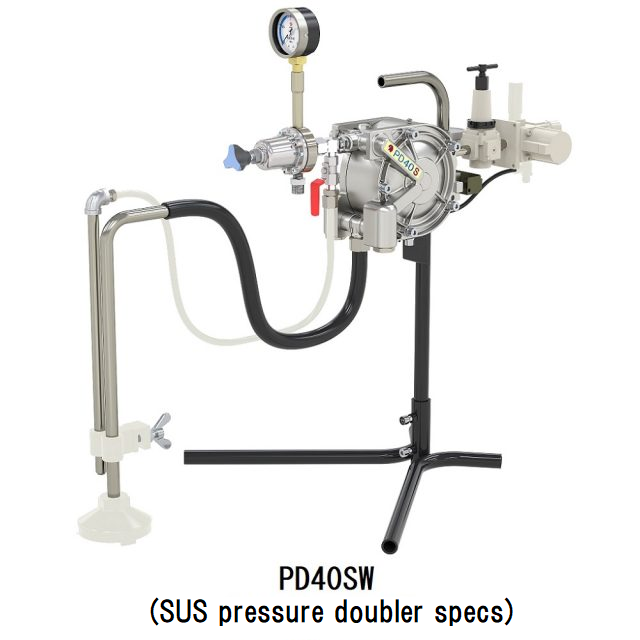

- A pressure increase valve produces twice as much air pressure as the standard type, making it ideal for high-viscosity

paints such as water-based and hybrid paints.(PD40SW)

- The paint path is constructed entirely of stainless steel, preventing corrosion with water-based paints, etc.(PD40S)

- Combined with a high-viscosity regulator, paint is supplied at a steady rate, providing uniform film quality.(PD40S)

|

Model |

PD40 |

PD40L |

PD40S |

PD40SW |

|---|---|---|---|---|

|

Pressure ratio |

1:1 |

1:2 |

||

|

Max. paint pressure |

0.7MPa |

1.0MPa |

||

|

Max. air pressure |

0.7MPa |

1.0MPa |

||

|

Max. rate of discharge*1 |

20L/min |

10L/min |

20L/min |

15L/min |

|

Air hatch |

G1/4(PF1/4) |

|||

|

Fluid outlet |

Rc3/8(PT3/8) |

G3/8(PF3/8) | ||

|

(Low-pressure regulator hatch bore G1/4(PF1/4)) |

(Low-pressure regulator hatch bore G3/8(PF3/8)) | |||

|

Dimensions (W x D x H) |

470×540×690mm |

470×640×690mm |

||

|

Mass |

8.5kg |

13.5kg |

15kg |

|

| Required compressor | 1.5kw(2PS) | |||

| Structure/features | Standard specs | Shortened cleaning specs | SUS specs | SUS pressure doubler specs |

※1…Liquid: Water, pump unit

No.450

Dec., 2025

Electrostatic Heat-Resistant Coating for Microwave Oven Grill Frames ⁂

- Used paint:

- Liquid paint

Learn more

Introduction:To address aging equipment and improve coating quality and labor efficiency, the company renewed automatic spray guns on two coating lines.

Benefits

1. Paint consumption and touch-up work were significantly reduced, increasing correction-free production and improving process efficiency.

2. Uniform, high-quality finishes were consistently achieved, contributing to labor savings.

3. The upgrade of the automatic spray guns delivered measurable gains in quality, productivity, and cost efficiency with minimal investment.

Return to overview

No.447

Aug., 2025

Electrostatic Coating of Die-Cast Products ⁂ ⁂ ⁂ ⁂ ⁂

- Used paint:

- Liquid paint

Learn more

Introduction To resolve issues caused by aging coating guns on its two-component coating line, such as declining quality, reduced productivity, and environmental concerns, the company upgraded its coating equipment and facilities.

Benefits

1. The use of base resin and hardener, along with the amount of waste generated, was reduced by 15%.

2. Improvements in coating efficiency enabled an increase in line speed by 0.2 m/min.

3. The combination of highly efficient automatic coating guns and a multi-color two-component mixing system capable of high-quality coating created a synergistic effect, achieving both cost reduction and productivity improvement.

Return to overview

No.442

Feb., 2025

Electrostatic coating of building materials

- Used paint:

- Liquid paint

Learn more

Introduction : Due to the aging of the automatic coating system for topcoat, the reciprocating and automatic spray guns were updated.

Benefits :

1. The coating quality has improved significantly.

2. The high coating efficiency of the automatic spray gun improved productivity and reduced paint usage by 10%.

3. Corrective coating and maintenance work have been significantly improved, reducing the burden on workers.

4. By maximizing the spray gun's performance, it is expected that paint usage will be further reduced.

Return to overview

Series Mutual Documents

PDF(319.40 KB)

Please feel free to contact us for any inquiries or questions regarding the coating equipment and engineering.

Please feel free to contact us for any consultations or questions related to the services of Coating Equipment Division.