PRODUCTS

-

High-grade mix precision

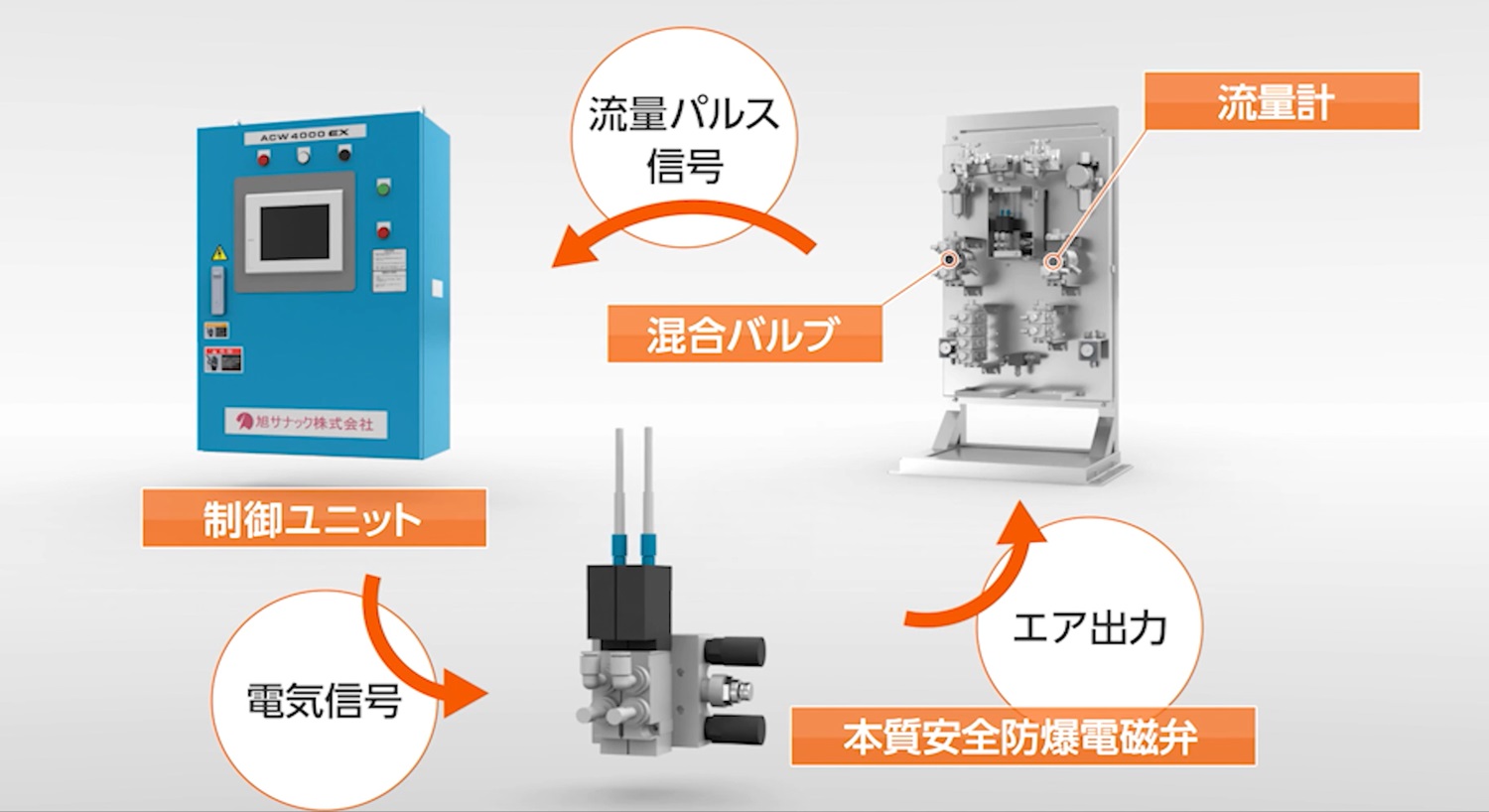

Unique patented technology provides a high-grade mix precision when using multiple coating guns, with an error factor of +/-5% or less during flow change. Two-component mixing provides highly-stable dispersion mixing with our unique “mixing hose” and “power mixer” combination.

-

Easy to clean

A simply constructed “mixing hose” (patent pending) and easy-to-clean “power mixer” (international patent pending) greatly reduce the amount of residue and defects.

-

Compatible with multiple paint colors

Standard equipped with a color change valve for flexibility when it comes to using multiple paint types and colors (max. 21 colors).A highly-efficient “power mixer” is equipped, making water-based two-component mixing possible with multiple cleaning agents.

-

Industry management functionality

Multiple types of data are recorded to memory, including a work life management function, all error detections, the amount of paint used, and industry performance management data.Communication function (optional) improves process management.

-

Diverse variations

Other than the floor set standard type in and outside the booth, wall-attachment types, portable, light-weight robot mounted types, etc. are available for a flexible assortment of settings and places.

| Model | ACW4000EX Series | |

| Corresponding to the number of colors | 3-color, 5-color, 7-color (base compound = max. 21 colors, hardening agent max. 21 types, thinner max. 21 types) | |

| Mix ratio | 1:5~30:1 (Three-component specifications 1:5:30~29:1:1) | |

| Mix precision | Within ±5% | |

| Paint viscosity | 20mPa・S~300mPa・S | 20mPa・S~3,000mPa・S |

| Max. discharge correspondence | 50~1,000mL/min | 200~2,000mL/min |

| Max. durable liquid pressure | 1.5MPa | 25MPa |

| Dimensions |

Control Unit:W550×H800×D300mm Mixing Unit:W534×H920×D293mm(low pressure) W790×H1,100×D320(high pressure)※ |

|

| Weight |

Control Unit:80kg Mixing Unit:40kg(low pressure) 60kg(high pressure)※ |

|

| By explosion-proof mixing unit | Intrinsic safety explosion-proof specs (certified for domestic labor) | |

| Power supply voltage | AC100V~240V | |

| Power consumption | 50W | |

| Wetted material | Stainless steel, teflon, polyester resin, tungsten carbide | |

| Main applied materials | Two-component urethane paint, two-component epoxy paint, water-based two-component urethane paint | |

| Remarks | For low pressure | For high pressure |

※Depends on the number of valves.

No.447

Aug., 2025

Electrostatic Coating of Die-Cast Products ⁂ ⁂ ⁂ ⁂ ⁂

- Used paint:

- Liquid paint

Learn more

Introduction To resolve issues caused by aging coating guns on its two-component coating line, such as declining quality, reduced productivity, and environmental concerns, the company upgraded its coating equipment and facilities.

Benefits

1. The use of base resin and hardener, along with the amount of waste generated, was reduced by 15%.

2. Improvements in coating efficiency enabled an increase in line speed by 0.2 m/min.

3. The combination of highly efficient automatic coating guns and a multi-color two-component mixing system capable of high-quality coating created a synergistic effect, achieving both cost reduction and productivity improvement.

Return to overview

No.441

Jan., 2025

Electrostatic coating of controller exterior panel

- Used paint:

- Liquid paint

Learn more

Introduction : Improving workability and productivity was a challenge.

Benefits : Color changes were done by inserting and removing the paint hose because there was only one paint route. By replacing it with a reciprocator featuring independent left and right control and a two-component coating system, it was possible to secure a separate paint route for each. It is expected that the complicated color change process will be significantly simplified and productivity will nearly double.

Return to overview

No.386

Mar., 2019

金属制品的涂装

- Used paint:

- Liquid paint

Learn more

同为涂装专业制造厂家,贵司需要对应的被涂物种类繁多,材料包括钢铁、铝、镁等多个种类。通过导入能够智能往复机和远程操作的平板电脑终端确立了可以对应小批量多品种的生产、可以缩短更换颜色的时间、减少涂料用量的优势,实现了提升涂装效率和生产效率的效果。

Return to overview

Series Mutual Documents

PDF(1009.09 KB)

Please feel free to contact us for any inquiries or questions regarding the coating equipment and engineering.

Please feel free to contact us for any consultations or questions related to the services of Coating Equipment Division.